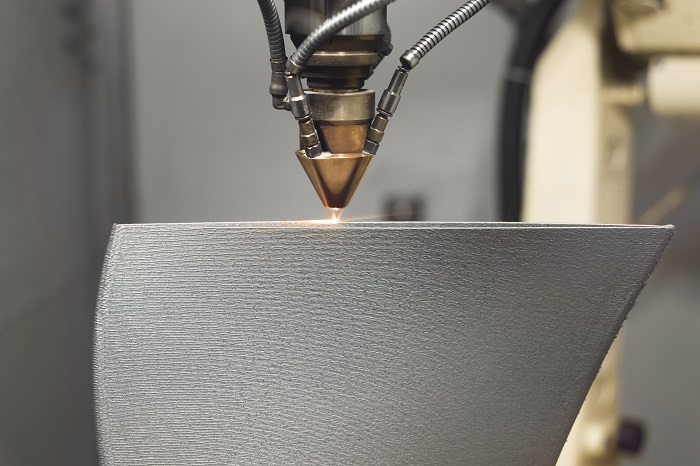

Industrial ovens are an integral part of the 3D metal printing process. The continuously evolving printing process technology starts with the creation of a 3D model or design. This digital design is then used to create a mold for the metal piece desired. Next, the mold is placed into an industrial oven, heated to very high temperatures, usually around 1,400°F (760°C). This extreme heat melts the metal, allowing it to form the desired shape as the mold dictates. Once cooled and hardened, the piece is removed from the oven and is ready for use.

Industrial ovens are an integral part of the 3D metal printing process. The continuously evolving printing process technology starts with the creation of a 3D model or design. This digital design is then used to create a mold for the metal piece desired. Next, the mold is placed into an industrial oven, heated to very high temperatures, usually around 1,400°F (760°C). This extreme heat melts the metal, allowing it to form the desired shape as the mold dictates. Once cooled and hardened, the piece is removed from the oven and is ready for use.

By using industrial ovens like JPW customizes and designs in the 3D metal printing process, businesses can achieve higher productivity without compromising quality or safety. JPW has been producing ovens for 3D metal printing customers for several years. Their ovens are designed to save energy and eliminate emissions, helping businesses reduce their environmental footprint while achieving desired levels of quality and performance. Other features that come with a JPW oven that make them suitable for 3D metal printing include air circulation systems that evenly distribute heat throughout the chamber, specialized trays, and pallets to maximize efficiency, temperature control systems to adjust the chamber’s environment, and insulated walls to reduce energy losses. JPW’s industrial ovens are also easy to maintain; their advanced filtration system keeps the air quality in the chamber clean, and their intuitive control panel allows businesses to monitor and adjust temperatures easily. Furthermore, safety is always a priority; JPW’s ovens come equipped with sophisticated fire suppression systems and emergency shut-off valves for added protection.

3D metal printing is an excellent way for businesses to quickly create custom parts and products with higher levels of accuracy and quality. Companies can save money by using an industrial oven from JPW while producing safe products that meet their customers’ needs.

Since 3D metal printing has a wide range of applications, it has the potential to revolutionize manufacturing for many businesses. This holds especially true in healthcare and how physicians treat their patients. For example, 3D metal printing has made its way into the medical industry by enabling the development of custom implants or prosthetics explicitly tailored for individual patients. It can also be used to create complex medical instruments that were not possible with traditional manufacturing processes.

3D metal printing has changed how products are designed, developed, and manufactured. It can be used to produce parts that were impossible with traditional methods. The technology also enables new design opportunities in product development, providing companies with faster turnaround times and improved customer satisfaction. As the technology continues to develop and advance, we will see even more uses for this groundbreaking process in both industrial and medical applications.

Why Choose JPW for your 3D Printing Manufacturing Needs?

The potential of 3D metal printing is limitless, and industrial manufacturers will benefit the most from this progressive technology. Using a JPW industrial oven or furnace for their 3D metal printing needs, industrial manufacturers can rest assured that their 3D metal printing manufacturing needs are met with the highest quality and most efficient solutions available, enjoying improved productivity, cost savings, and highly customized parts for a wide variety of industrial applications.

In addition to an excellent, American-made product, you receive more than just a reliable, well-constructed oven when you purchase one of our ovens. You receive unmatched customer service and our commitment to quality and service. Contact us today for your additive manufacturing needs.