Continuous Process Ovens

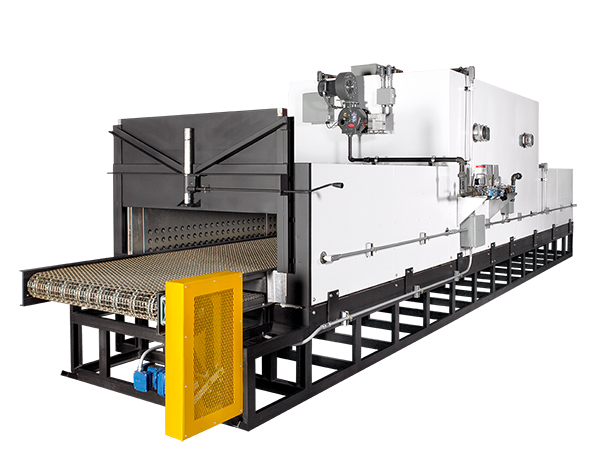

Continuous Process Ovens, as utilized across the formidable spectrum of industries from aerospace to automotive, encapsulate the pinnacle of industrial processing technology. They are not just machines but the backbone of manufacturing processes that demand precision, efficiency, and reliability. JPW’s continuous process ovens, specifically designed with welded steel structural units and heavy-gauge interiors, exemplify durability and performance that is second to none. These ovens operate at the cutting edge, with capabilities to reach temperatures up to 1250°F, a testament to their versatility in handling a diverse array of applications including, but not limited to, tempering, annealing, curing, pre-heating, heat-treating, drying, heat-shrinking, and heat-forming.

But what sets these continuous process ovens apart is not just their robust build or high-temperature thresholds. It is their innate design intelligence that caters to operational efficacy and ease. The heavy gauge aluminized steel or stainless-steel interiors are not only built for endurance but also for ease of maintenance and cleaning, ensuring that downtime is minimized and productivity is maximized. The accessibility of the interior, combined with an effective air distribution system, ensures uniformity in process conditions, a critical factor for achieving consistent quality outcomes.

Safety and compliance are paramount in industrial operations, and JPW’s continuous process ovens rise to this call. By the control panels being UL-approved, they meet stringent safety standards, providing reassurance of their operational integrity. The availability of simple to complex control systems further enhances their adaptability, enabling precision control over processing conditions tailored to the specific needs of each application.

In industries where the margin for error is negligible and the demand for quality is uncompromising, investing in the right processing equipment is not a choice but a necessity. Continuous process ovens offered by JPW represent not just equipment but also a strategic investment in quality, efficiency, and reliability. They are crafted to meet the rigorous demands of various industries, ensuring that whatever the application, from aerospace components that demand the utmost precision to automotive parts requiring high-grade finishes, these ovens are designed to deliver optimal outcomes consistently. This is a commitment to excellence, a pledge that JPW stands by with each continuous process oven it designs and manufactures, making it a trusted partner in industrial success.

Continuous Process Ovens available include:

Continuous Process Ovens available include:

- Flat conveyor belt

- Chain conveyor

- Ferris wheel

- Carousel

- Overhead trolley

- Serpentine

- Chain-on-edge

- Spindle

- Slat type

- Strip cure

- Print plate

- Pusher ovens

- Dog beams

- Wash-draw furnaces

- Multi-tier

Standard features:

- Welded steel structural unit that is built to last

- Heavy gauge aluminized or steel interior

- Easily accessible interior for maintenance and cleaning

- Effective air distribution system

- UL-approved 508A

- Simple or complex control systems available

- Temperatures up to 1250°F

Optional features:

- Zone temperatures (multiple heat zones)

- Process time

- Circulating fan speeds

- Extended loading and unloading zones

- Special belt construction or attachments

- Cooling zones to reduce part temperature

- PL automation

Continuous Process Ovens are used in a variety of industries, such as aerospace, defense, fiber optics, wood and metal finishing, plastics, rubber, industrial processing, pharmaceutical, electronics, printing, and automotive.

Looking to heat something up? You can count on us! We offer custom options in a large selection of sizes at affordable prices. Contact us today to learn more.