In today’s competitive manufacturing world, efficiency and precision are paramount. To keep up with industry demands, businesses adopt cutting-edge solutions like walk-in ovens. This blog article will explore the ins and outs of walk-in ovens and how they can enhance your industrial operations.

In today’s competitive manufacturing world, efficiency and precision are paramount. To keep up with industry demands, businesses adopt cutting-edge solutions like walk-in ovens. This blog article will explore the ins and outs of walk-in ovens and how they can enhance your industrial operations.

What is an Industrial Walk-In Oven?

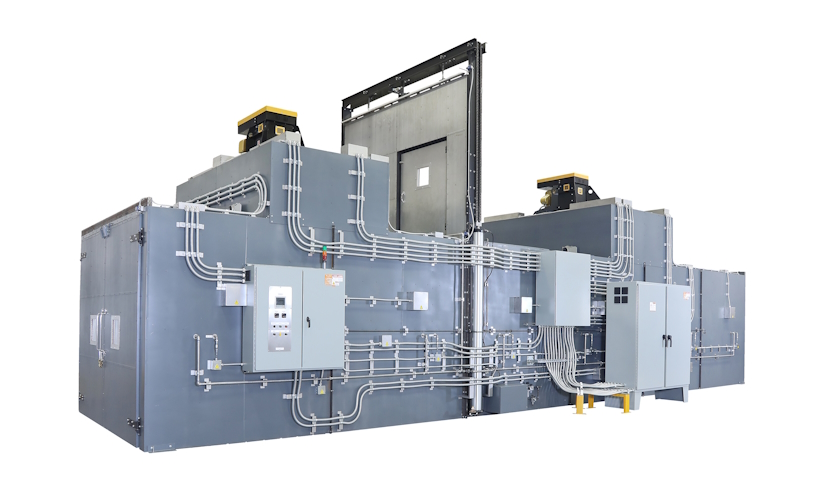

Industrial walk-in ovens are specialized heating chambers designed to process large quantities of materials or parts simultaneously. They are spacious enough to allow personnel or vehicles to enter, making them versatile for various applications.

Walk-in ovens are engineered for high performance and can handle a range of temperatures, often exceeding 1,000 degrees Fahrenheit. They are built to be durable and reliable, featuring robust construction to withstand daily industrial use. The key advantage? They allow for large-scale heating processes without sacrificing accuracy or quality.

Types of Industrial Walk-In Ovens

There are several types of walk-in ovens, each tailored to specific needs:

- Batch Ovens: These ovens process a batch of products simultaneously, offering flexibility and control over heating cycles. They are ideal for varied production schedules.

- Continuous Process Ovens: Designed for constant production processes, continuous ovens allow materials to move through the heating chamber on a conveyor system.

- Curing Ovens: Used primarily for curing coatings, adhesives, or composites, these ovens enhance and stabilize the material’s properties.

Each type of walk-in oven serves a unique purpose, ensuring a perfect fit for your specific industrial needs.

Industries Frequently Using Walk-In Ovens

Walk-in ovens are indispensable across various industries:

- Aerospace: Utilized to cure composite materials and heat-treating metal components, walk-in ovens ensure high-quality aircraft parts.

- Pharmaceuticals: Critical in sterilizing equipment and materials, these ovens help maintain stringent health standards.

- Automotive: Used for drying and curing paints and coatings, ensuring durable and aesthetically pleasing finishes.

- Metal Finishing: Essential for heat-treating metals to improve strength and durability, vital for manufacturing metal parts.

Their versatility and reliability make walk-in ovens a staple in many industries.

Key Features of Walk-In Ovens

What sets industrial walk-in ovens apart are their advanced features:

- Temperature Uniformity: Ensures consistent heating, which is crucial for quality control.

- Customizability: Options for specialized racks, carts, and shelving configurations to meet specific operational needs.

- Energy Efficiency: Modern designs focus on reducing energy consumption while maintaining high performance.

These features contribute to walk-in ovens’ high efficiency and effectiveness, making them an essential tool in industrial applications.

Applications of Walk-In Ovens

The applications of walk-in ovens are as diverse as the industries they serve:

- Heat-Treating: Essential for altering the physical and chemical properties of metals and alloys.

- Drying and Curing: Critical for removing moisture and curing coatings, adhesives, and composites.

- Sterilization: Used in the pharmaceutical and medical industries to sterilize instruments and materials.

These applications highlight the versatility and indispensability of walk-in ovens in modern manufacturing processes.

Benefits of Using Walk-In Ovens

Walk-in ovens offer numerous benefits:

- Improved Efficiency: Large capacity allows the processing of multiple items simultaneously, reducing production time.

- Enhanced Quality Control: Consistent temperature and humidity control ensure high-quality outcomes.

- Cost Savings: Energy-efficient designs lower operational costs, providing long-term savings.

These benefits demonstrate why investing in a walk-in oven can be a game-changer for your business.

JPW Industrial Ovens and Furnaces – A Leader in Innovation

At JPW Industrial Ovens and Furnaces, we don’t just lead—we redefine the industrial oven industry. Our walk-in ovens go beyond standard solutions, offering unmatched customizability and efficiency. Boasting capacities that extend up to 8,000 cubic feet, our ovens set a benchmark in the industry, accommodating large-scale operations with ease. Whether you need intricate shelving configurations or specialized racks and carts, we tailor every detail to fit your unique operational requirements.

Our services cater to a wide array of industries, including aerospace, pharmaceuticals, automotive, and metal finishing. We provide solutions engineered to meet each sector’s specific needs, ensuring reliability, safety, and superior energy efficiency. For example, our ovens are essential in composite curing and heat treatment in the aerospace industry, which demands precise temperature control and uniform heat distribution. For the pharmaceutical industry, our high-performance ovens aid in drying, sterilization, and other critical applications requiring stringent regulatory compliance.

Automotive manufacturers also benefit significantly from our top-tier ovens, which are integral in drying paint, coatings, and heat-treating components. Similarly, the metal finishing industry relies on our specialized ovens for processes like powder coating and annealing, where consistently high temperatures are crucial for optimal results.

Additionally, JPW Industrial Ovens and Furnaces prides itself on exceptional service and support. We offer comprehensive consultation services to understand your needs and provide the most effective solutions. Our team of experts works closely with you from the initial design phase to installation and maintenance, ensuring that your operations are streamlined and efficient. We also provide after-sales support to ensure your equipment remains in optimal condition, offering maintenance plans and rapid-response services to address any issues that may arise.

In an era where energy efficiency and sustainability are more critical than ever, JPW Industrial Ovens and Furnaces are designed with advanced features that minimize energy consumption without compromising performance. We incorporate cutting-edge insulation materials and employ sophisticated control systems that optimize energy usage, contributing to reduced operational costs and a smaller environmental footprint.

Ready to transform your manufacturing process? Contact JPW Industrial Ovens and Furnaces today to find out how our walk-in ovens can meet your needs. Your path to industrial oven and furnace efficiency starts here.