News

Trout Run, PA (May 1, 2018) – JPW Industrial Ovens and Furnaces, an industrial oven manufacturer based near Williamsport, Pa., has added a second manufacturing facility to its operation. The new plant is expected to create 25 new jobs within the next two years.

Cabinet ovens, also referred to as reach-in ovens, are recommended for use in an industrial setting when the product you are working with can be easily inserted into the oven by hand.

Lab/bench ovens are typically used in the industrial setting when small batches of product are needed or the size of the workspace is limited. These ovens are often positioned on a table or bench, but can also be floor mounted depending on the setting. They often use trays to bring the part being processed into the oven.

The DB64 is a high-temp drop bottom oven that operates at 950F and processes materials through aluminum heat treating and aging. This specific oven is designed to treat materials for the aerospace industry

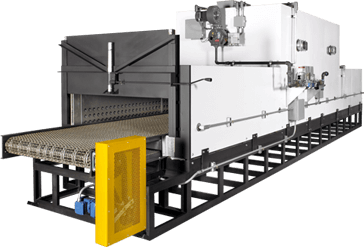

The BC100 is a batch conveyor oven for T5 aging. The BC100 features electric powered rollers that transport baskets into a heated chamber

The ST216 is an aging oven that operates at 400F. This oven was designed for a client in the aerospace industry for treating of aircraft parts

This month we focus on Dennis Folk, skilled painter at JPW. Dennis has been a part of the team for over 7 years and is dedicated to creating a quality finish for all JPW products.

JPW recently filled an order for a BC455, a batch conveyor to perform T5 aging on aluminum automotive parts. This highly efficient oven is engineered to be fully automated.

This month we focus on Ryan Deuel, an experienced machine operator and fabricator at JPW. Ryan contributes his skills to oven fabrication process through professional operation of the sheer, CNC punch press, press brake and other equipment.

The HT343 is rated at 1250F and measures 36Wx36Hx48D. This model will be used for heat treating metals. It features combination airflow and even a custom color specific to the customer’s request.